Choosing the right CNC lathe for your manufacturing business is a critical decision that can significantly impact productivity, efficiency, and cost-effectiveness. A well-chosen lathe can improve production processes and ensure that your operations run smoothly and consistently, while the wrong choice can lead to delays, increased costs, and reduced output. In this article, we will discuss the key factors to consider when selecting a CNC lathe, providing valuable insights and guidance to help you make the best choice for your specific needs and requirements.

Assess Your Production Needs

Before selecting a CNC lathe, it's essential to have a clear understanding of your production requirements. Factors to consider include production volume, part complexity, and material types. These factors will heavily influence the choice of CNC lathe, as different models have varying capabilities and specifications.

For example, if you primarily produce high-volume, simple parts, you may require a lathe with fast cycle times and straightforward programming capabilities. Conversely, if you manufacture complex, low-volume parts, a lathe with advanced programming features and the ability to handle a wide range of materials may be more suitable.

Machine Size and Workspace Considerations

Another important factor to consider when choosing a CNC lathe is the size and capacity of the machine relative to your available workspace. Factors to consider include the lathe's footprint, weight, and power requirements.

Before making a decision, evaluate your available workspace to ensure that the chosen lathe will fit comfortably, with sufficient room for operation, maintenance, and material handling. Additionally, consider the power supply and any infrastructure requirements, such as ventilation or cooling systems, to ensure compatibility with your existing facilities.

Lathe Specifications and Features

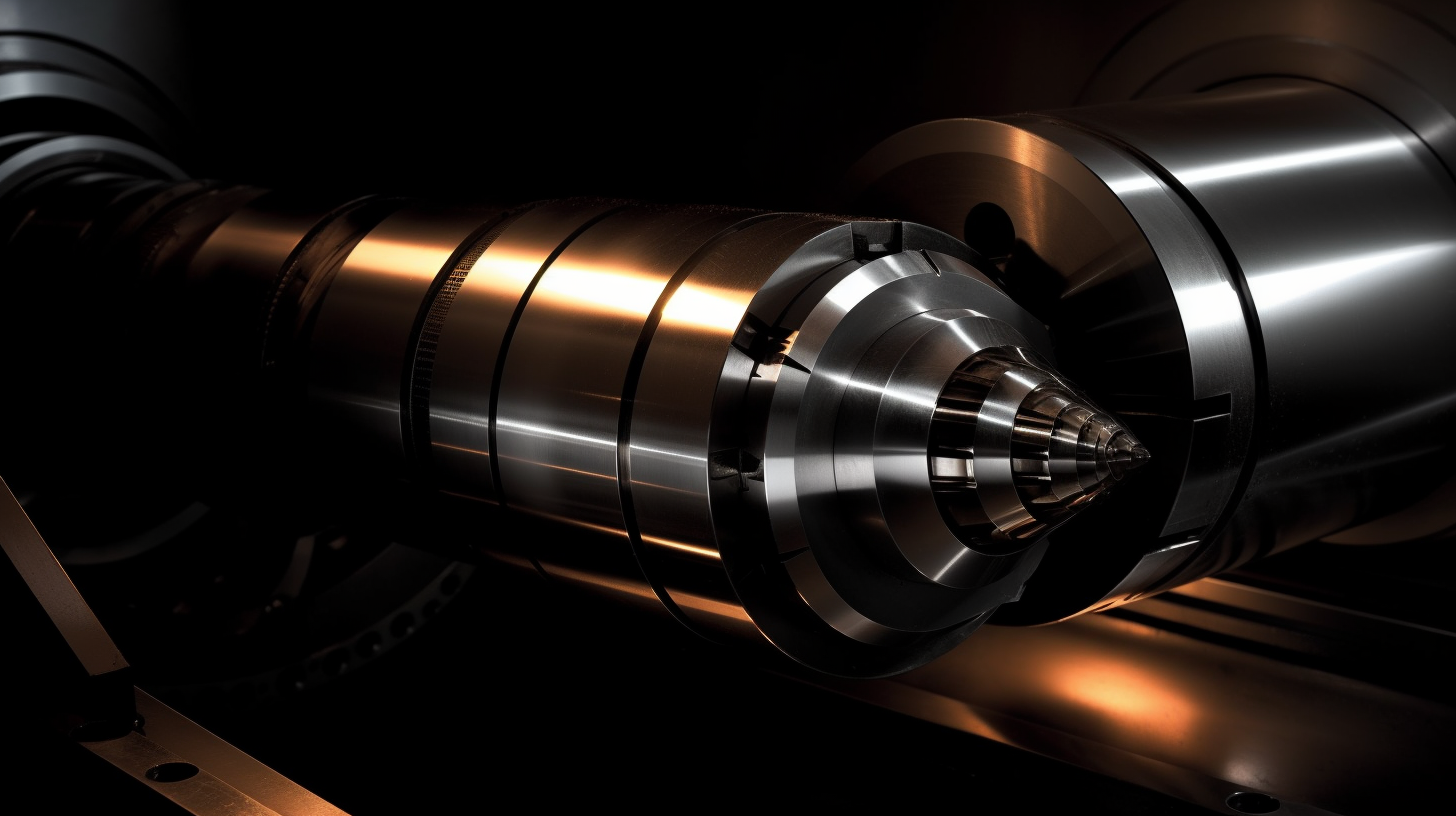

When selecting a CNC lathe, it's essential to carefully consider the machine's specifications and features. Key specifications to evaluate include spindle speed, horsepower, and tooling capacity, as these directly impact the lathe's production capabilities and efficiency.

For instance, a higher spindle speed may be necessary for machining harder materials or achieving tight tolerances, while a larger tooling capacity allows for greater flexibility in the types of parts that can be produced. When comparing different CNC lathe models, carefully consider how their specifications align with your production requirements and priorities.

Software and Control System

The CNC lathe's software and control system play a crucial role in the selection process. Factors to consider include ease of use, programming capabilities, and compatibility with existing systems.

Ideally, the chosen lathe's control system should be user-friendly and intuitive, allowing operators to quickly learn and adapt to its programming language and features. Additionally, the system should be compatible with your existing CAD/CAM software, streamlining the production process and minimizing the need for additional software investments.

Budget and Total Cost of Ownership

Finally, it's essential to consider budget and total cost of ownership when selecting a CNC lathe. Factors to consider include the initial cost of the machine, ongoing maintenance costs, and tooling expenses.

While a lower-priced lathe may seem like an attractive option initially, it's important to evaluate the machine's overall value and return on investment. A more expensive lathe with advanced features and lower maintenance costs may ultimately be more cost-effective in the long run. Carefully weigh the pros and cons of each option to determine the best fit for your budget and production needs.

Conclusion

Selecting the right CNC lathe for your manufacturing needs is a crucial decision that requires careful consideration of factors such as production requirements, machine size, specifications, software and control systems, and budget. By taking the time to evaluate your options and align them with your specific needs, you can make an informed decision that will help ensure the success and efficiency of your production processes. With the right CNC lathe in place, your manufacturing operations will be well